Why is it important to have industrial weighing scales calibrated?

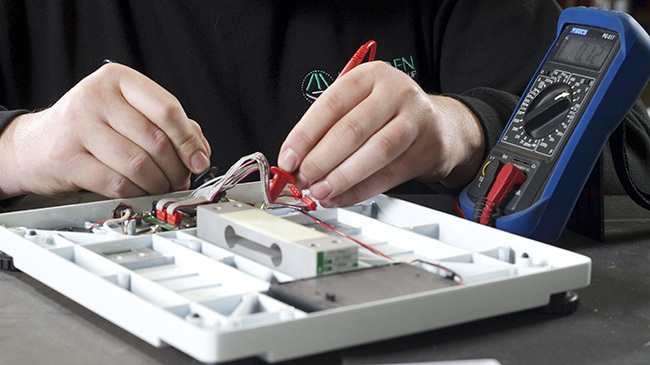

Weighing scale calibration can be defined as reading a weight measurement and comparing it to a known standard.

The official definition from The International Bureau of Weights and Measures states: “Operation that, under specified conditions, in a first step, establishes a relation between the quantity values with measurement uncertainties (of the calibrated instrument or secondary standard) and, in a second step, uses this information to establish a relation for obtaining a measurement result from an indication.”

Over time, industrial scales tend to lose their accuracy. This means that it is necessary to recalibrate scales during their period in use to ensure they are weighing accurately.

What happens to scales that are not calibrated?

Naturally, a scale’s accuracy will degrade over time. However there are some factors that make the scale fall out of calibration much quicker: such as over-use and taking the scale into a different environment. Electrical overloads and general accidents can also send the scale out of calibration - so it is important to handle your purchase with care.

Having your weighing scales serviced acts as an MOT to bring them up to standard and ensures readings are showing just as accurately as when the scales were received. Recalibration should form part of a service check.

What makes calibration important?

Here are three reasons that make ensuring you have your weighing scales calibrated correctly important:

Processes are safeguarded

It is important in measuring weight that readings are accurate so to ensure safety. An example would be inaccurate readings for transporting goods – not only can the road and vehicle be damaged, the brakes can be affected making it dangerous for the driver, passengers and other road users, and financial penalties handed out.

Errors lead to costs

If orders come up short, it could negatively impact the entire supply chain and result in complaints from your customers. If orders are worth more than the value that they are sold for, it is lost revenue for the business.

Comply with regulation

If you are buying or selling based on weight of the goods, any scales used in your company for this purpose fall under regulatory standards. If your scale are weighing outside these tolerances, or your scale is not Trade Approved, it can result in fines. Outside of this, scale accuracy should fall into your quality system if you have one.

How do you know your scale needs calibrating?

The scale does not show a zero reading

When there is nothing on the scale it should display Zero on the indicator display. If not, it suggests that recalibration is required.

A predefined exact weight is showing incorrectly

When a known weight is applied, the indicator must display the exact amount of applied weight.

Some parts feel more loose

Loose fittings may be noticeable when a scale needs a recalibration service.

To find out more, click here.

A Marsden industrial service contract includes a once or twice yearly service visit which will include re-calibration of your scale.

For more information on scale servicing, and having your weighing scales calibrated, click here or email service@marsdengroup.co.uk.